That has a sound business enterprise credit rating, exceptional after-sales provider and modern producing facilities, we now have earned an superb standing amongst our buyers across the world for Reliable Supplier China Former Factory Making Double Layer Corrugated and Ibr Trapezoidal Metal Steel Roof Panel Wall Sheet Roll Forming Machine, Influenced from the swift building marketplace of the quick food and beverage consumables all over the planet , We’re wanting forward to operating with partners/clients for making good results together.

That has a sound business enterprise credit rating, exceptional after-sales provider and modern producing facilities, we now have earned an superb standing amongst our buyers across the world for China Roll Forming Machine, Cold Roll Forming Machine, With a fully integrated operation system, our company has won a good fame for our high quality goods, reasonable prices and good services. Meanwhile, we have established a strict quality management system conducted in material incoming, processing and delivery. Abiding by the principle of “Credit first and customer supremacy”, we sincerely welcome clients from home and abroad to cooperate with us and advance together to create a brilliant future.

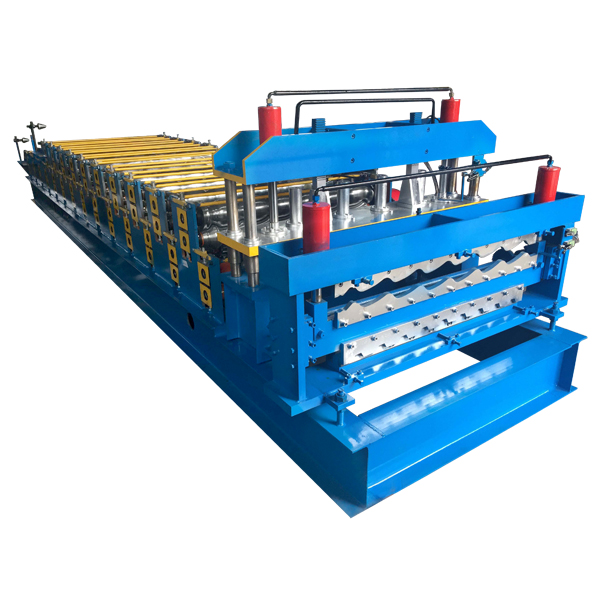

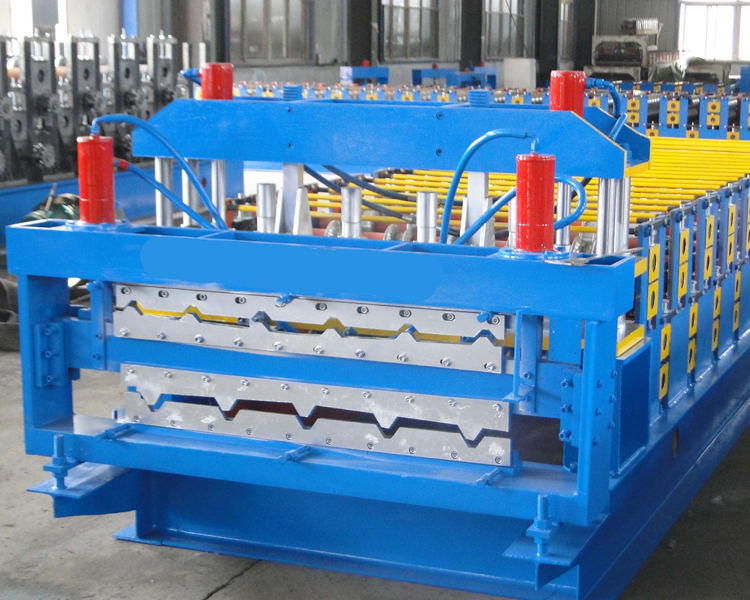

Double layer roof panel roll forming machines can press two types of tiles of different versions.

|

Roof roll forming machine parameters |

||

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

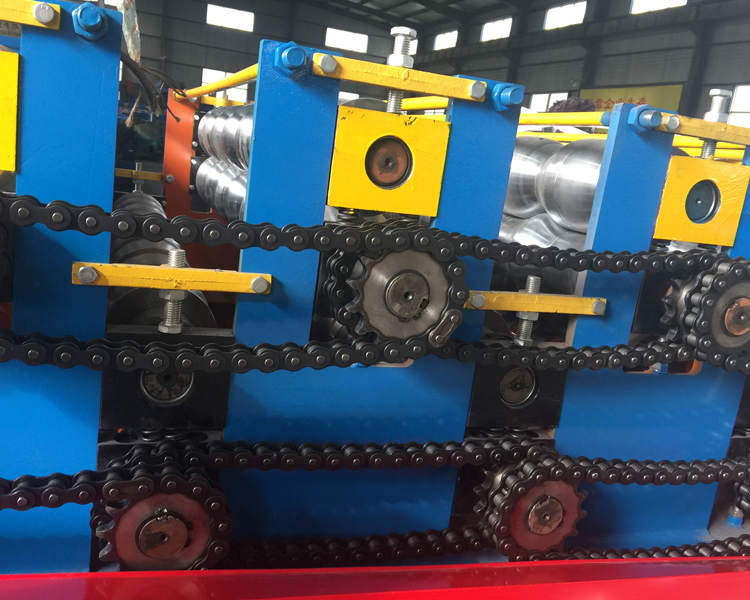

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 840mm, 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Components:

Manual un-coiler: 1 set

Guiding platform: 1 set

Coil strip leveler: 1 set

Main machine of roll forming: 2set

Electric-motor: 1 set

Cutting device: 2 set

Hydraulic station: 1 set

PLC control: 1 set

Supporter table: 1 set

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).