Short Lead Time for Corrugated Steel Sheet Wall Panel Tile Making Machine - High reputation Roll Formers Corrugated Steel Sheet Metal Roof Wall Panel Glazed Tiles Roll Forming Machine – Haixing Industrial Detail:

To meet the customers’ over-expected gratification , we have our robust crew to offer our best over-all support which includes marketing, income, coming up with, production, excellent managing, packing, warehousing and logistics for High reputation Roll Formers Corrugated Steel Sheet Metal Roof Wall Panel Glazed Tiles Roll Forming Machine, If you’re intrigued within our products, you should truly feel cost-free to ship us your inquiry. We sincerely hope to establish win-win business interactions along with you.

To meet the customers’ over-expected gratification , we have our robust crew to offer our best over-all support which includes marketing, income, coming up with, production, excellent managing, packing, warehousing and logistics for Corrugated Sheet Making Machine, Steel File Making Machine, Wall Panel Roll Forming Machine, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade solutions in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

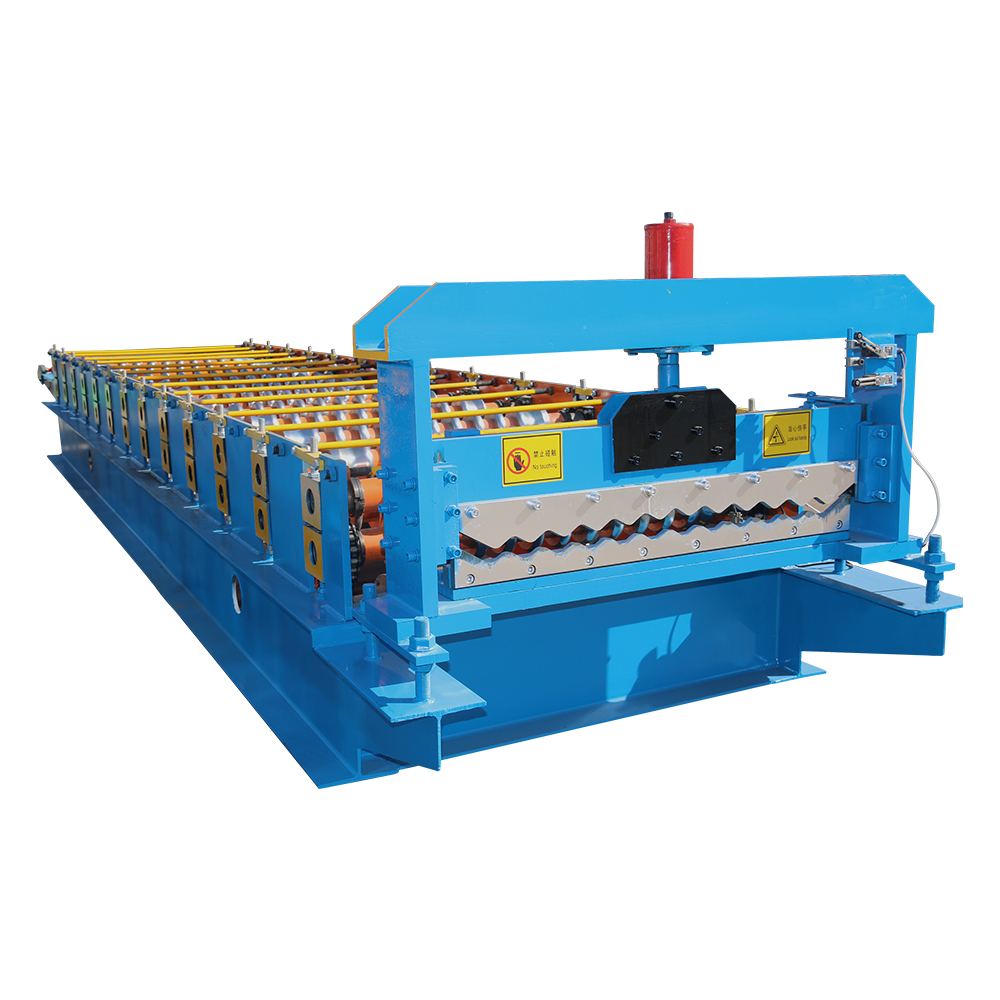

Colored Glazed Tile Roofing Sheet Roll Forming Machine parameters list:

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 836mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

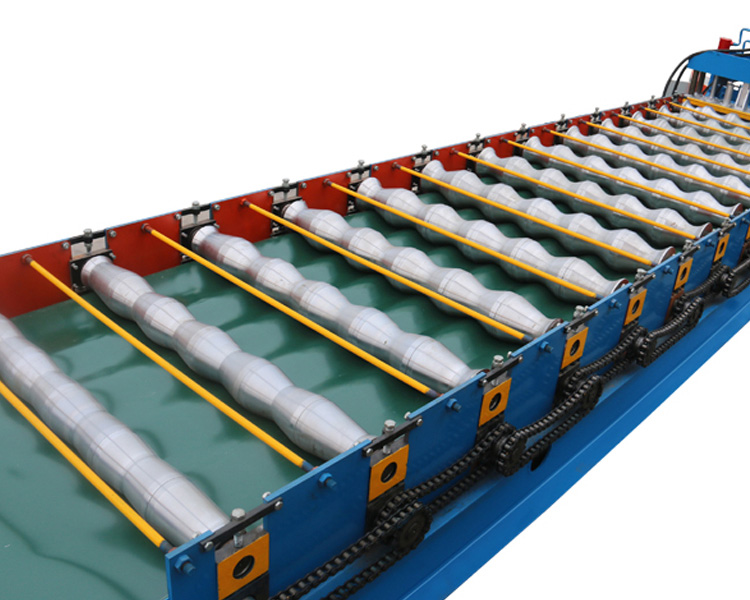

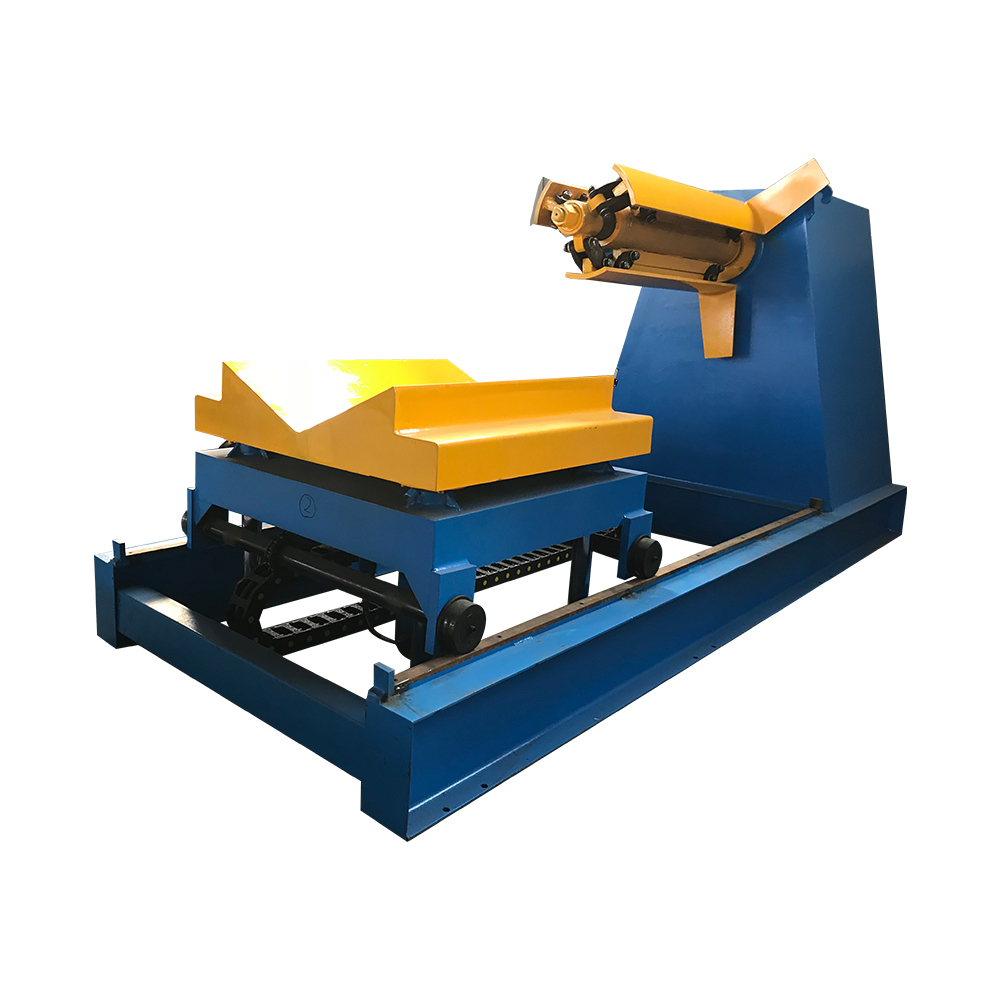

Colored glazed tile roofing sheet roll forming machine picture display

Company profile

Color steel roll forming machine is very popular used to make steel roof and wall panel, we have a wide range of cold forming machines such as roof roll forming machines, Light steel keel roll forming machines, and slitting lines and so on.

Product detail pictures:

Related Product Guide:

How to unlock the Pack-a-Punch in Voyage of Despair | Ibr Roof Sheet Making Machine

Springfield company begins making tape for cassettes | Ibr Roof Sheet Making Machine

Short Lead Time for Corrugated Steel Sheet Wall Panel Tile Making Machine - High reputation Roll Formers Corrugated Steel Sheet Metal Roof Wall Panel Glazed Tiles Roll Forming Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

factory low price Stud Machine - Color Coated ...

-

Renewable Design for Stainless Steel Slitting M...

-

Hot Sale for Metal Door Forming Machine - Stee...

-

Factory source Tile Moulding Machine - Wholesa...

-

China wholesale 2mm Sheet Bending Plate Bending...

-

factory Outlets for Rainwater Pipe Making Machi...