No matter new customer or old customer, We believe in long term and trusted relationship for Short Lead Time for Glazed Tile Arch Curving Roofing Forming Machinery, Competitive value with top quality and satisfying company make us earned extra shoppers.we wish to work with you and request common development.

No matter new customer or old customer, We believe in long term and trusted relationship for Best Glazed Tile Arch Curving Roofing Forming Machinery, Glazed Tile Arch Curving Roofing Forming Machinery, With a state-of-the-art comprehensive marketing feedback system and 300 skilled workers’ hard work, our company has developed all kinds of products ranging from high class, medium class to low class. This whole selection of fine products offers our customers different choices. Besides, our company sticks to high quality and reasonable price, and we also offer good OEM services to many famous brands.

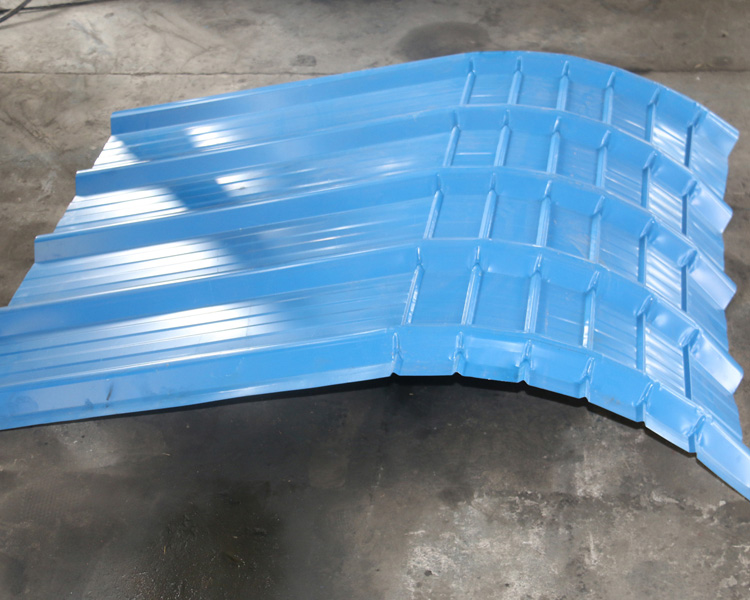

Application of Curved Roof Panel Roll Forming Machine

For architecture: making roof panel, wall panel, ceiling panel, etc.

For Industry: making refrigerating room panel, automobile panel, electric appliance housing, etc.

|

Curved Roof Panel Roll Forming Machine parameters |

||

| 1 | Main motor power | 5.5kw, 3 phase or as your request |

| 2 | Hydraulic motor power | 4kw |

| 3 | Hydraulic Pressure | 10-12MPa |

| 4 | Voltage | 380V /3phase/ 50 HZ (or as your requirement) |

| 5 | Control System | PLC Delta Inverter |

| 6 | Main Frame | 300mm/350mm H-Beam or 350mm |

| 7 | Backboard Thickness | 16mm |

| 8 | Chain Size | 1 Inch |

| 9 | Feeding Material | color steel coils |

| 10 | Feeding Thickness | 0.3-0.8mm |

| 11 | Feeding Width | 100-1200mm |

| 12 | Effective width | 840-1050mm |

| 13 | Productivity | 0-15/min |

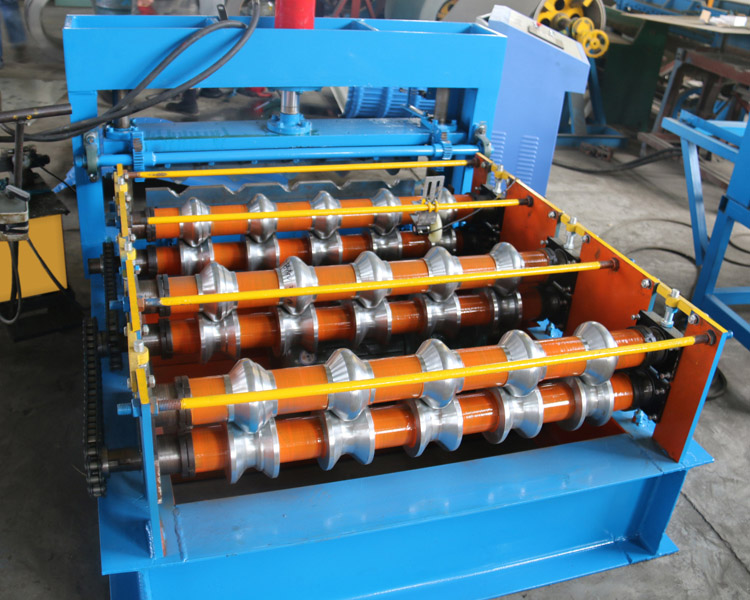

| 14 | Roll Station | 13 roll steps(according to different design) |

| 15 | Roller Diameter | 70mm(depend on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-Plating Size | 0.05mm |

| 19 | Overall Size | 6800*1400*1150mm |

| 20 | Total Weight | 5.8T |

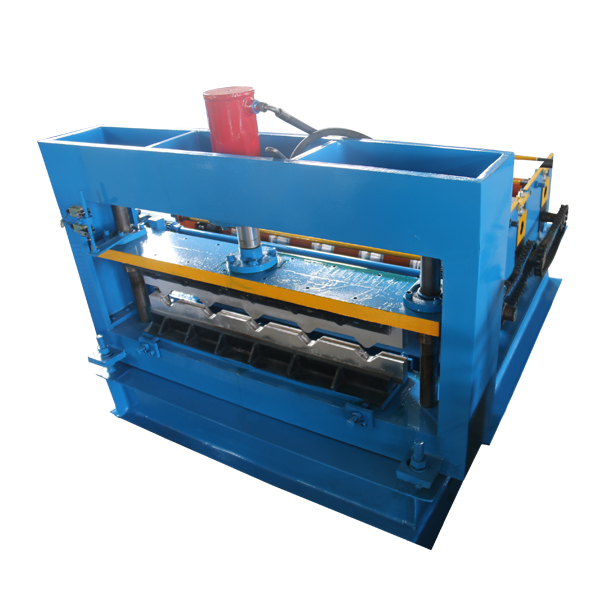

Machine Photos:

Package and shipment details:

1. Main roll forming machine package by plastic film

2. Main machine spare parts package by paper box

3. We have a professional technician load to ensure that the goods are loaded into the container without any damage.

4. Transportation: machines need one 20 feet container to hold.

5. Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you.

-

China Manufacturer for Frp Grp Fiberglass Corru...

-

Cheapest Factory Double Layer Wall Tile Making ...

-

China Supplier Cold Roll Forming Machine,Metal ...

-

Special Design for Trapezoidal Roof Panel Roll ...

-

factory Outlets for Industrial Level Wood Acryl...

-

Hot-selling Latest Technology Steel Door Frame ...