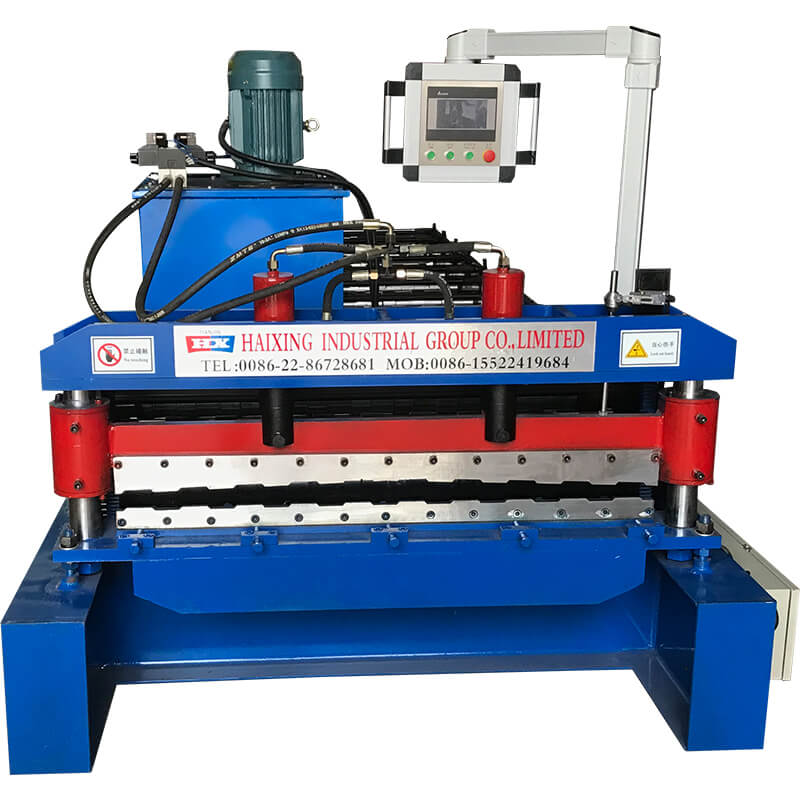

T sharp aluminum roof making machine parameters

| Hydraulic pressure | 10-12MPa according to oil pump and pump motor | Main motor power | 4/5.5/7.5KW or as actual demands |

| Voltage | 380V/ 3 phase/ 50 Hz (or as your requirements) | Hydraulic motor power | 3/4/5.5KW or as actual demands |

| Main frame | 350/400H beams according to machine demands | Control system | Automatic PLC control system |

| Wall sheet thickness | 16/18/20/22mm according to machine demands | Feeding thickness | 0.3-0.8 mm |

| Feeding material | Galvanized steel coil/color steel coil/aluminum steel coil | Roller material | 45# steel |

| Productivity | 0 – 25m/min (according to machine specification) | Cutter material | Cr12MOV |

| Roll station | Common 11 or 25rolls (according to different design) | Cr-plating size | 0.05 mm |

| Roller diameter | 70/75/80mm (depends on different design) | Chain size | 1/1.2inch according to machine demands |

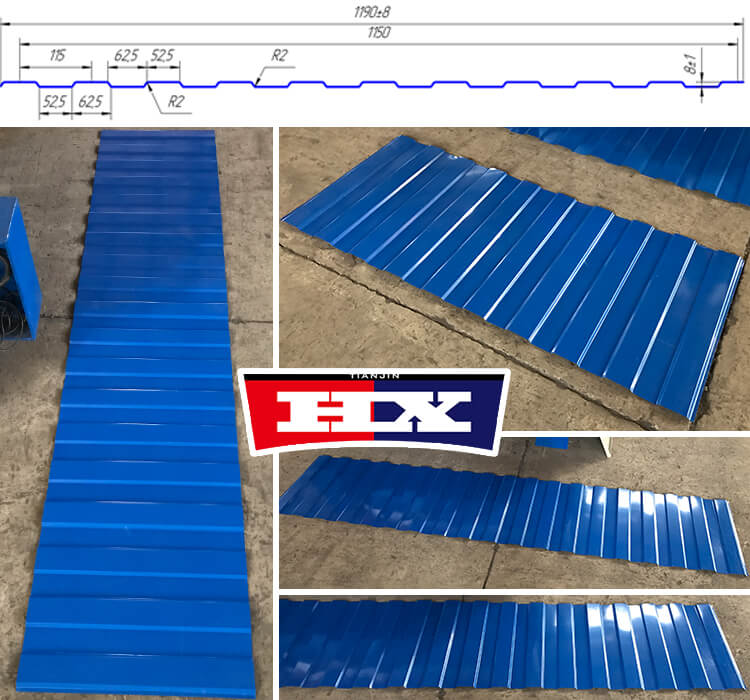

Final product display

Main details of T sharp aluminum roof making machine

We offer our customers easy-broken parts for free.

Application

Roof roll forming machinery could produce metallic roofing tile, trapezoidal or sinusoidal roofing sheet, floor deck, C and Z purlin, expressway guardrail, channel and stud, roller shutter and sandwich panel, etc. Customized profiles and requirements are acceptable, and assistant equipment such as hydraulic decoiler, auto stacker, etc.

Packaging details

1. T sharp aluminum roof making machine are nude packing (If you need, we can also packed it with water-proof plastic).

2. PLC control system and motor pump are packed with waterproof paper, spare parts in a carton box.

3. One set of machine needs a 40′ container to shipping.