Wholesale T Grid Ceiling Structural Steel Roll Forming Machine - 100% Original Factory Automatic Dpeed Light Steel Keel Frame Cold Roll Forming Machine – Haixing Industrial Detail:

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and service capabilities for 100% Original Factory Automatic Dpeed Light Steel Keel Frame Cold Roll Forming Machine, For even more inquires remember to do not hesitate to get in touch with us. Thank you – Your support continuously inspires us.

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and service capabilities for Automatic Dpeed Light Steel Keel Frame Cold Roll Forming Machine, Keel Roller Former Production Line, Stud And Track Colding Forming Machines, Our products and solutions are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

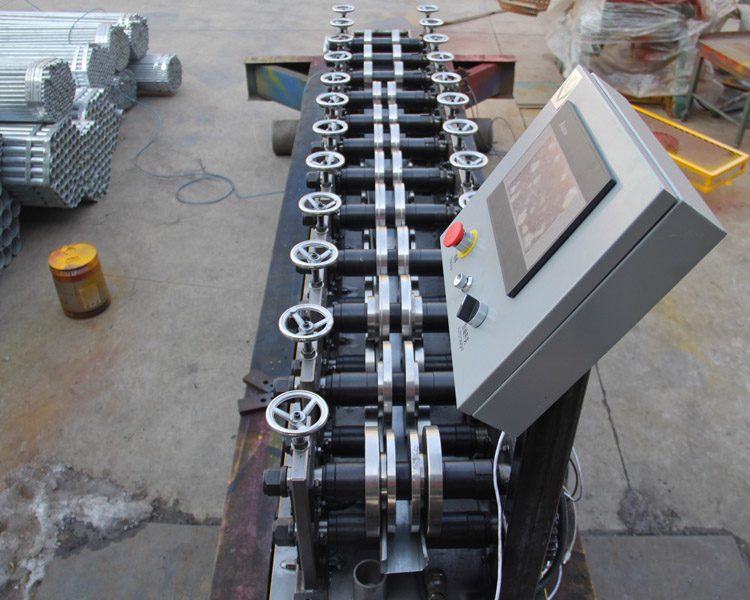

Equipment components of C channel light steel keel making machine:

Manual decoiling, roll forming machine, computer control system, hydraulic control system, cutting, run out table.

|

Light steel keel roll forming machine parameters |

||

| 1 | Main motor power | 4kw/3 phase (or as your request) |

| 2 | Hydraulic motor power | 3kw |

| 3 | Hydraulic pressure | 10~12MPa |

| 4 | Voltage | 380V/3 phase/50HZ (or as your request) |

| 5 | Control System | PLC Delta /Panasonic/Siemens/ |

| 6 | Main Frame | 300/350mm H-Beam |

| 7 | Backboard Thickness | 17/20mm |

| 8 | Chain size | 1/2inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.18~0.8mm |

| 11 | Feeding width | Better as your profile or from our design |

| 12 | Effective width | Better as your profile or from our design |

| 13 | Productivity | 0-3min |

| 14 | Roll station | 11~20 roll steps(according to different design) |

| 15 | Roller diameter | 75mm (according to different design) |

| 16 | Roller material | 45#steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-Plating size | 0.05mm |

| 19 | Overall size | 5000mm*1000mm*1500mm |

| 20 | Total weight | 2~12T |

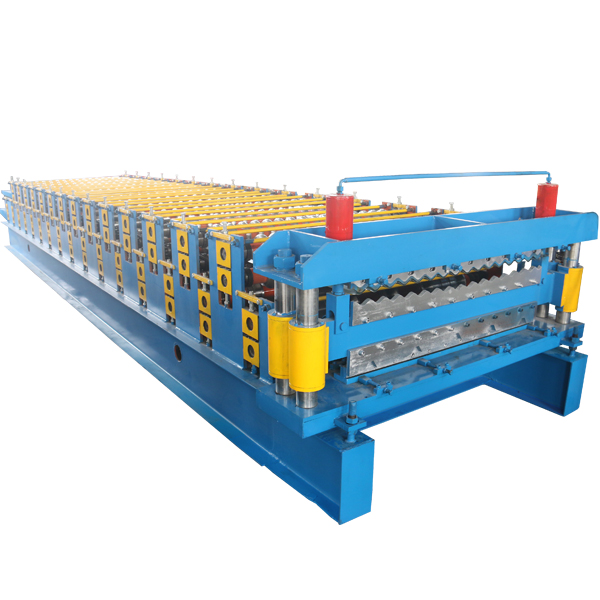

C channel light steel keel roll forming machine picture display

Packaging Details:

1. Machine is covered by plastic film

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Product detail pictures:

Related Product Guide:

Carnival cruise ship rescues man who plunged from Norwegian vessel | Ibr Roof Sheet Making Machine

Oden Technologies raises $10M to bring data analytics to manufacturing | Steel Downpipe Roll Forming Machine

Wholesale T Grid Ceiling Structural Steel Roll Forming Machine - 100% Original Factory Automatic Dpeed Light Steel Keel Frame Cold Roll Forming Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

factory Outlets for Automatic C Stud Roll Formi...

-

China Factory for Curved Machine - Double Laye...

-

Reasonable price Combined Keel Ceiling Machine ...

-

Chinese Professional Metal Deck Floor Machine -...

-

OEM/ODM Supplier Steel Decking Roll Forming Mac...

-

Cheapest Factory Roofing Press Machine - Low p...