Adhering to the principle of “quality, service, efficiency and growth”, we have gained trusts and praises from domestic and international client for China New Product Roller Shutter Door Roll Forming Machine/gutter Roll Forming Machine/roll Forming Machine, We are also continuously hunting to establish relationship with new suppliers to supply progressive and intelligent alternative to our valued shoppers.

Adhering to the principle of “quality, service, efficiency and growth”, we have gained trusts and praises from domestic and international client for Gutter Roll Forming Machine, Roll Forming Machine, Roller Shutter Door Roll Forming Machine, We only supply quality products and we believe this is the only way to keep business continue. We can supply custom service too such as Logo, custom size, or custom products etc that can according to customer’s requirement.

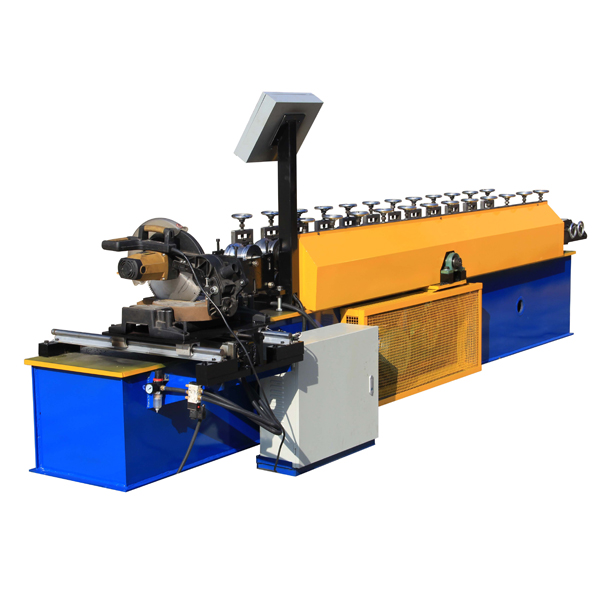

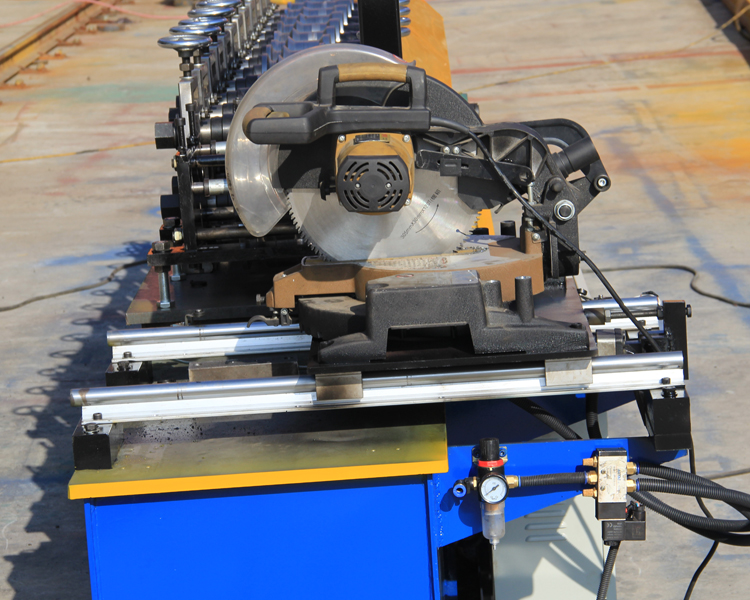

Machine parameters

|

Roller shutter door roll forming machine |

||

| 1 | Materials specification | Aluminum, galvalume, galvanized and pre-painted galvanized steel. |

| 2 | Thickness | 0.5mm to 1.0mm. |

| 3 | Main motor power | 4.5kw. |

| 4 | Hydraulic station power | 3kw. |

| 5 | Feeding width | Depends on the model of profile. |

| 6 | Yield stress | 235Mpa(33KSI) ~ 350Mpa |

| 7 | Roll forming speed | 12-15 m/minute. |

| 8 | Cutting tolerance | +/-2.5mm(length≤5000mm); +/-3.0mm(5000mm) |

| 9 | Manual uncoiled | Max. Capacity: 3000kgs

Manual decoiler |

| 10 | Coil inner diameter | 508mm/610mm |

| 11 | Voltage | 380v/50hz/3 phase |

| 12 | Numbers of stands | 12 stands/stations/pairs for each roll forming system |

| 13 | Roller material | High grade No.45 forged steel, coated with hard chrome. |

| 14 | Active shaft material | High grade No.45 carbon wrought steel, which can improve the integrated mechanic feature of the shaft. |

| 15 | Electric elements | PLC control panel, transducer imported from Mitsubishi of Japan.

Other elements are from famous suppliers of China. |

| 16 | Cutter blades | Cr12 mold steel with quenched treatment. |

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Sales service:

1. We provide the technical support for whole life of our machines.

2. If buyers need the technician to go abroad , we will arrange the technician, but the buyers should take all the cost , including visa, round trip ticket etc.