Our primary intention will be to provide our clientele a serious and responsible small business relationship, giving personalized attention to all of them for Leading Manufacturer for Plastic Hdpe Monofilament Rope Production Line Extruder Machine, Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us!

Our primary intention will be to provide our clientele a serious and responsible small business relationship, giving personalized attention to all of them for Hdpe Monofilament Rope Extruder Machine, Hdpe Monofilament Rope Production Line, Plastic Monofilament Rope Extruder Machine, We’ve got established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we have been looking forward to even greater cooperation with overseas customers based on mutual benefits. Make sure you feel free to contact us for more details.

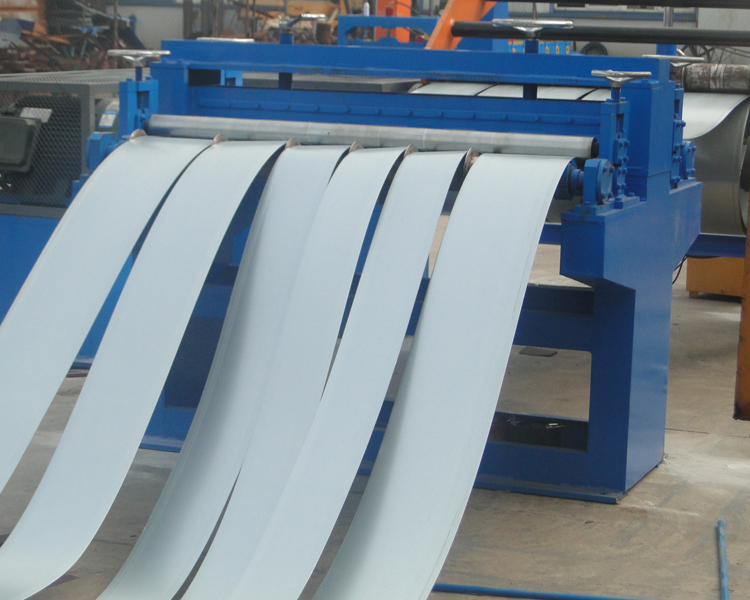

Slitting machine line cuts the metal coil into strips of various widths required, and then collects the strip into small rolls for use in the next process.

|

Slitting line machine parameters |

||

|

Raw Material (if the material is stainless steel, please tell in advance) |

1 | Material: carbon steel and others |

| 2 | The thickness of the material: 0.4mm-6mm. | |

| 3 | Width: 10mm, 12mm, 15mm, 20mm, 25mm, 30mm, 40mm, 50mm, 60mm | |

| 4 | Input width: 600-1600mm | |

|

Hydraulic decoiler with car |

1 | The inner size: 450–610mm |

| 2 | The Max width: 1250mm | |

| 3 | The capacity: 15T 20Ton or more | |

|

Flatting and Cutting System |

1 | 2 shafts for feeding coil, 9 shafts for flatting |

| 2 | material of flatting: 42CrMo heat treated 50-52. | |

| 3 | hydraulic system. | |

| 4 | 2 sets cutting blade | |

| 5 | width of cutting: 600mm–1220mm. | |

| 6 | the material of blade mould: Gr12MoV | |

| 7 | power: 22KW Motor with ZQ650 Reducer | |

|

Slitting system |

1 | The width range: 200–1300mm |

| 2 | The precious of the width: ±1mm | |

| 3 | The speed of slitting: 25m/min | |

| 4 | The width can be change. | |

| 5 | Material of the slitting: Cr12MoV. | |

| 6 | Hardness of slitting blade: HRC5860. | |

| 7 | Slitting: 2~3mm 6 lines. | |

| 8 | Quantity of blades: 10 sets. | |

| 9 | Width of side scrap: 3-15mm | |

| 10 | The precious of side scrap: ±0.5mm | |

| 11 | Quantity of side scrap: 2 strips | |

| 12 | Power of the slitting: 37KW, 1000r/min, with ZQ750 Reducer. | |

|

Control System |

1 | Screen: 3.2inch button screen |

| 2 | PLC: Delta | |

|

Electrical collecting machine with car |

1 | Material inner: 550-650mm |

| 2 | Max Coil width: 1500mm | |

| 3 | Carrying capacity: 5T | |

| 4 | Automatic relax or collect | |

| 5 | Power: 22KW | |

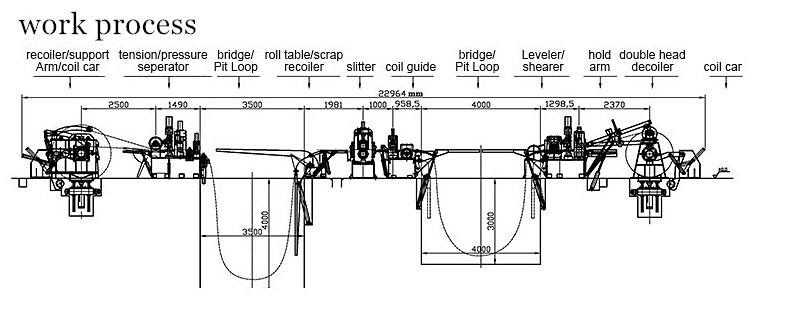

Working process

Decoiler —-flatting and cutting—slitting—–flatting and collecting

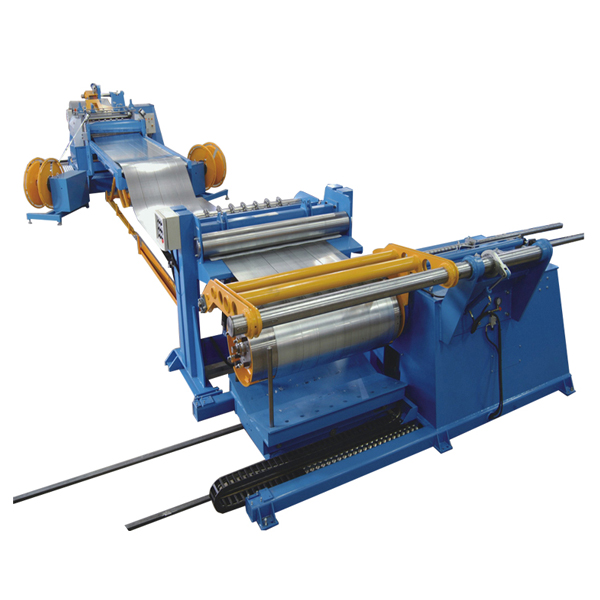

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.