For being the stage of realizing dreams of our employees! To build a happier, much more united and much more expert staff! To reach a mutual gain of our prospects, suppliers, the society and ourselves for China Gold Supplier for GF20 CNC/manual construction building steel bar bender 6-16mm/6-28mm rebar stirrup making bending machine for sale, We are able to customize the solutions according to your needs and we can easily pack it for you when you purchase.

For being the stage of realizing dreams of our employees! To build a happier, much more united and much more expert staff! To reach a mutual gain of our prospects, suppliers, the society and ourselves for , In order to meet our market demands, we now have paied more attention to the quality of our products and solutions and services. Now we can meet customers’ special requirements for special designs. We persistently develop our enterprise spirit “quality lives the enterprise, credit assures cooperation and keep the motto in our minds: customers first.

|

4 meters hydraulic roof sheet bending machine parameters |

||

|

1 |

Cutting &Hydraulic type |

Double guide pillar |

|

2 |

Hydraulic motor power |

3kw |

|

3 |

Hydraulic Pressure |

10-12MPa |

|

4 |

Voltage |

380V/3phase/50 HZ(or as your requirement) |

|

5 |

Cutting drive |

Decelerating motor+ Chain drive gear all by high-frequency |

|

6 |

Control System |

Panasonic PLC |

|

8 |

Bending degree |

0-90 |

|

9 |

Operating mode |

Button+ Mitsubishi |

|

10 |

Main Frame |

300mm/350mm H-Beam or 350mm |

|

11 |

Backboard Thickness |

17mm |

|

12 |

Feeding Material |

GI/PPGI/PPGL |

|

14 |

Feeding Thickness |

0.2-0.8mm |

|

15 |

Feeding Width |

1-4m |

|

16 |

Effective width |

1-4mm |

|

17 |

Productivity |

0-60times/min |

|

20 |

Roller material |

45# steel |

|

21 |

Cutter material |

Cr12 mould steel heat-treated hardness of HRC = 60-62 degrees |

|

22 |

Brand Square |

A3 35mm thick plate arch |

|

22 |

Cr-Plating Size |

0.05mm |

|

23 |

Overall Size |

4300*1200*2100mm |

|

24 |

Total Weight |

1.8T |

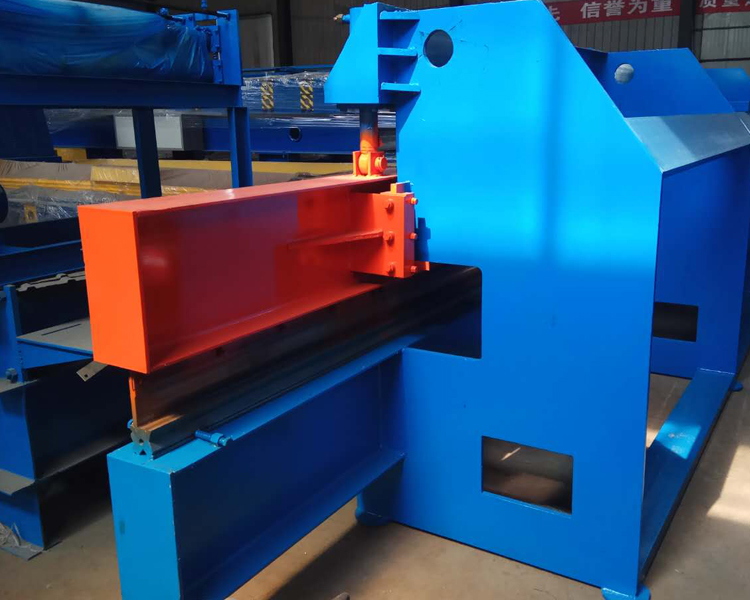

Machine photos

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

-

Cheap price China Full Automatic Operating Galv...

-

Wholesale ODM La Suspension T Grid Para Falso T...

-

New Delivery for Manual Bending Machine Metal L...

-

Discountable price Aluminum Corrugated Roofing ...

-

Ordinary Discount Manual Metal Bemo Standing Se...

-

Cheapest Price Wall Angle Light Keel Roll Formi...