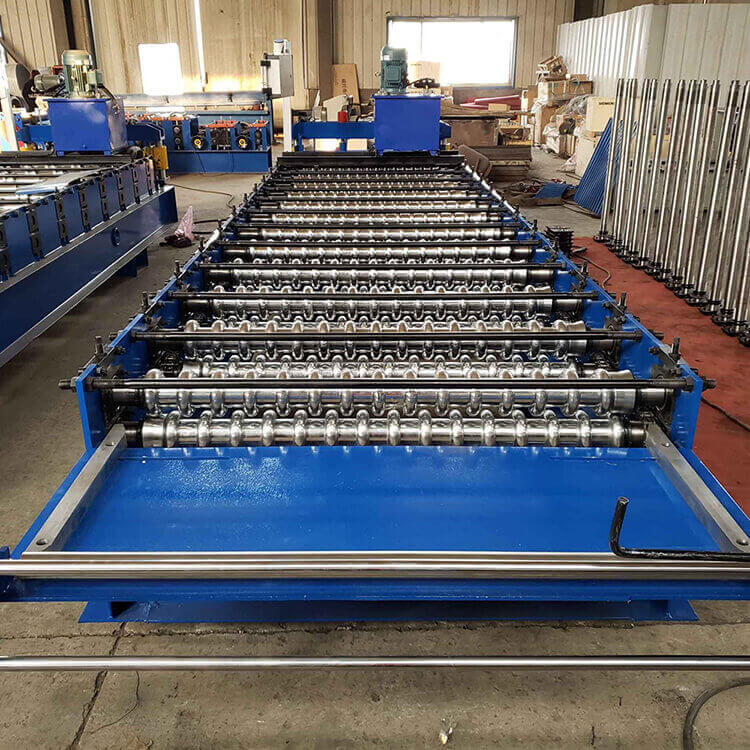

Galvanized corrugated roof sheet making machine’s technical parameters

| Length of the main part | About10500*1650*1500mm |

| Weight of main part | About 9.5 tons |

| Voltage | 380V/50HZ/3Phase (as customer’s request) |

| Roller fixer | Middle plate welded |

| Frame | 350H steel welded |

| Middle plate thickness | 18mm |

| Drive mode | Chain Drice |

| Material of rollers | 45# steel, surface hard chromium plating. |

| Material of shafts | 45# steel |

| Diameter of shafts | Φ80mm(depend on different design) |

| Number of rollers: | 29 rollers |

| Main power | 5.5kw |

| Cutting&Hydraulic | Double guide pillar |

| Hydraulic motor power | 3kw,4kw |

| Hydraulic Pressure | 10-12MPa |

| Cutting drive | Decelerating motor + Chain drive gear all by high-frequency |

| Control System | PLC system: Mitsubishi, Panasonic,Dental,Siemens,Schneider |

| Feeding Material width | Better as your drawing or from our designer |

| Feeding Thickness | 0.8~1.5mm |

| Effective width | Better as your drawing or from our designer |

| Productivity | 8-12/min |

| Package of machine | Waterproofing membrane, standard export packing |

Galvanized corrugated roof sheet making machine’s introduction and feature

1. The main parts: roll forming machine; molding press; cutting machine; PLC computer control; hydraulic system.

2. The machine is stable, with no noise, no shake.

3. Controlling by computer, PLC display, the operation is easy, running is steady and reliable, endurable.

4. Cutting machine is characterized by stable driving, easy operation.

5. The hydraulic system uses the CDF-10 hydraulic pump, long operating life, no noise.

6. Material: galvanized, colored steel or aluminum coil.

7. We can make and design the kinds of roll forming machines according to customer’s requests.

Our aim would be to fulfill our shoppers by offering golden company, very good value and good quality for , we have now 22 years experience of production and trading with the customers all over the world. Our clients mainly distributed in the North America, Africa and Eastern Europe. we can supply high quality products with the very competitive price.