The purchaser fulfillment is our primary focus on. We uphold a consistent level of professionalism, high quality, credibility and service for Factory For China High Stud and Track Speed Light Keel Roll Forming Machine, With a wide range, high quality, realistic price ranges and very good company, we are going to be your finest enterprise partner. We welcome new and previous buyers from all walks of lifetime to contact us for long run company associations and acquiring mutual good results!

The purchaser fulfillment is our primary focus on. We uphold a consistent level of professionalism, high quality, credibility and service for China Light Roll Forming Machine, Stud and Track Light Keel Roll Forming Machine, we sincerely hope to establish a good and long-term business relationship with your esteemed company through this opportunity, based on equality, mutual benefit and win-win business from now to the future. “Your satisfaction is our happiness”.

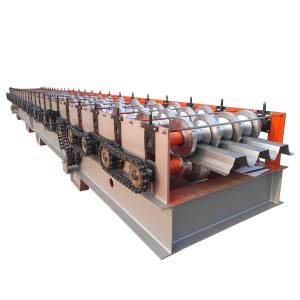

Our light gauge steel studs roll forming machine can be designed according to the buyer’s samples or drawings. The work Flow for the galvanized metal studs and tracks roll forming machine is as follows: Decoiler → Feeding Guide → Roll Forming → Cut-to-length → Run out table.

|

Automatic C Channel Light Keel Roll Forming Machine parameters |

||

| 1 | Suitable to process | Color steel plate |

| 2 | Width of the plate | As customer need |

| 3 | Thickness of the plate | 0.5-1.2mm |

| 4 | De-coiler | Manual one, can load 3 tons raw material |

| 5 | Rollers for forming | 18 rows |

| 6 | Diameter of the roller | Φ52mm |

| 7 | Rolling material | Carbon steel 45# |

| 8 | Main motor power | 4kW |

| 9 | Productivity | 8-12m/minute |

| 10 | Cutting method | Hydraulic mold cutting |

| 11 | Material of the cutting blade | Cr12 |

| 12 | Hydraulic cutting power | 3kW |

| 13 | Processing precision | Within 1.00mm |

| 14 | Control system | Delta PLC control |

| 15 | Side panel of machine | 25mm |

| 16 | Main structure of the machine | 300H steel |

| 17 | Weight | About 6.5T |

| 18 | Dimensions | 5.5*1.0*1.5m |

| 19 | Voltage | 380V/50Hz/3 phases (changeable as needs) |

Components:

Manual decoiler ——————————————1 set

Guiding platform —————————————–1 set

Main machine of roll forming ————————–1 set

Electric motor ———————————————1 set

Cutting device ———————————————1 set

Hydraulic station ——————————————1 set

PLC control ————————————————1 set

Supporter table ———————————————1 set

Machine details

Automatic C Channel Light Keel Roll Forming Machine Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).