Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction for OEM Manufacturer China Ibr/ Trapezoidal/ Corrugated Steel Roof Sheet Roll Forming Machine, Our concept will be to help presenting the confidence of each buyers with all the offering of our most honest support, and the right products.

Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction for China Ibr Roof Sheet Roll Forming Machine, Trapezoidal Roof Sheet Cold Roll Forming Machine, We aim to become the modern enterprise with the commercial ideal of “Sincerity and confidence” and with the aim of “Offering customers the most sincere services and best quality products”. We sincerely ask for your unchanged support and appreciate your kind advice and guidance.

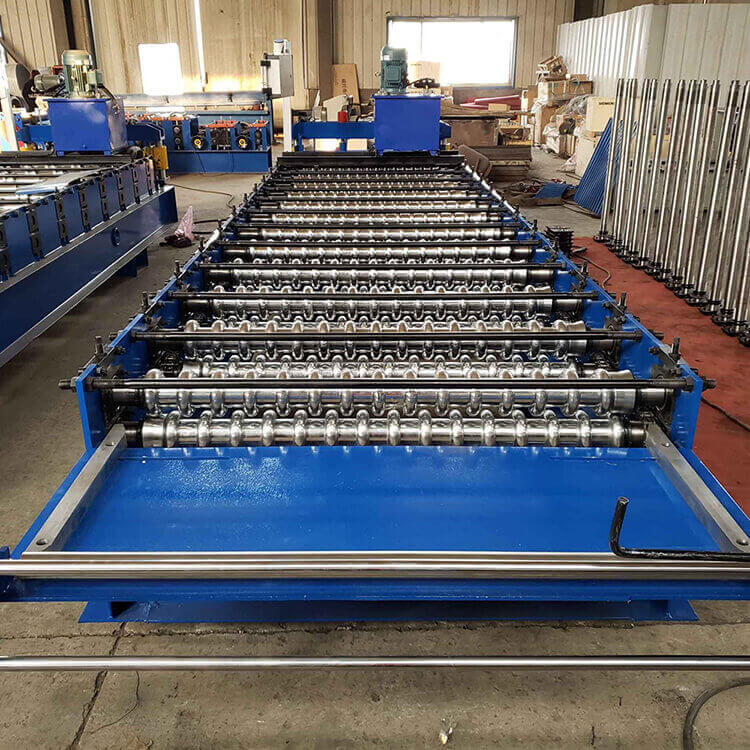

Color Steel Wave Roof Panel Roll Forming Machine’s technical parameters

| Length of the main part | About10500*1650*1500mm |

| Weight of main part | About 9.5 tons |

| Voltage | 380V/50HZ/3Phase (as customer’s request) |

| Roller fixer | Middle plate welded |

| Frame | 350H steel welded |

| Middle plate thickness | 18mm |

| Drive mode | Chain Drice |

| Material of rollers | 45# steel, surface hard chromium plating. |

| Material of shafts | 45# steel |

| Diameter of shafts | Φ80mm(depend on different design) |

| Number of rollers: | 29 rollers |

| Main power | 5.5kw |

| Cutting&Hydraulic | Double guide pillar |

| Hydraulic motor power | 3kw,4kw |

| Hydraulic Pressure | 10-12MPa |

| Cutting drive | Decelerating motor + Chain drive gear all by high-frequency |

| Control System | PLC system: Mitsubishi, Panasonic,Dental,Siemens,Schneider |

| Feeding Material width | Better as your drawing or from our designer |

| Feeding Thickness | 0.8~1.5mm |

| Effective width | Better as your drawing or from our designer |

| Productivity | 8-12/min |

| Package of machine | Waterproofing membrane, standard export packing |

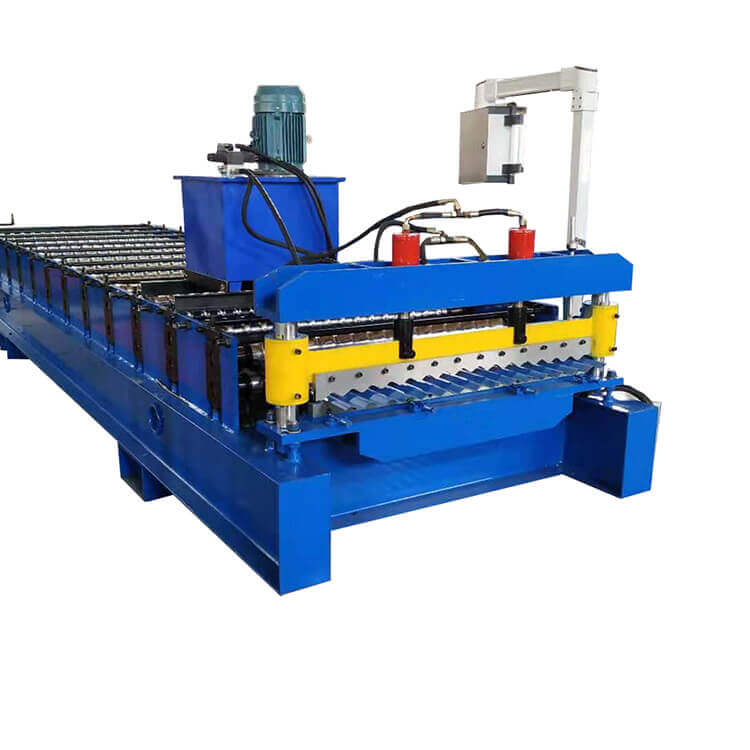

Color Steel Wave Roof Panel Roll Forming Machine’s introduction and feature

1. The main parts: roll forming machine; molding press; cutting machine; PLC computer control; hydraulic system.

2. The machine is stable, with no noise, no shake.

3. Controlling by computer, PLC display, the operation is easy, running is steady and reliable, endurable.

4. Cutting machine is characterized by stable driving, easy operation.

5. The hydraulic system uses the CDF-10 hydraulic pump, long operating life, no noise.

6. Material: galvanized, colored steel or aluminum coil.

7. We can make and design the kinds of roll forming machines according to customer’s requests.

Packaging Details

a.The main body of machine with water-proof plastic, then fixed to container by 8mm diameter steel wire and angle iron.

b.Rollers and shafts are covered with anti-rust oil.

c.PLC control system and motor pump are packed with waterproof paper and plastic film.

d.Spare parts in a carton box.

e.Manual decoiler was nude packing.

f.The output-table put into a carton box.

g.If the machine is too long, we will divide it into two parts and pack them in one package with steel wire.

h.Fit for ocean shipping.

Equipment placement:

The base surface of all equipment should be horizontal and hardened. The decoiler, roll forming machine ,center line of the discharge rack, molding machine and discharge table should be on the same straight line, and the left and right sides should not be inclined. The distance between the discharge rack and the forming host should be ≥3m. After the equipment is placed in a stable position, it should be fixed with anchor bolts.