We have now a hugely efficient team to deal with inquiries from buyers. Our goal is “100% client gratification by our solution high-quality, rate & our team service” and take pleasure in a great popularity among clients. With several factories, we will provide a wide assortment of Quality Inspection for small clay roof tile press machine/clay floor tiles machine/clay press tile machine made in China Zhengzhou, We will offer high-quality goods and great solutions at competitive price ranges. Start benefiting from our comprehensive services by contacting us today.

We have now a hugely efficient team to deal with inquiries from buyers. Our goal is “100% client gratification by our solution high-quality, rate & our team service” and take pleasure in a great popularity among clients. With several factories, we will provide a wide assortment of , We’ve got more than 200 staff including experienced managers, creative designers, sophisticated engineers and skilled workers. Through hard work of all employees for the past 20 years own company grew stronger and stronger. We always apply the “client first” principle. We also always fulfill all contracts to the point and therefore enjoy excellent reputation and trust among our customers. You are very welcome to personally visit our company.We hope to start a business partnership on the basis of mutual benefit and successful development . For more information make sure you do no hesitate to contact us..

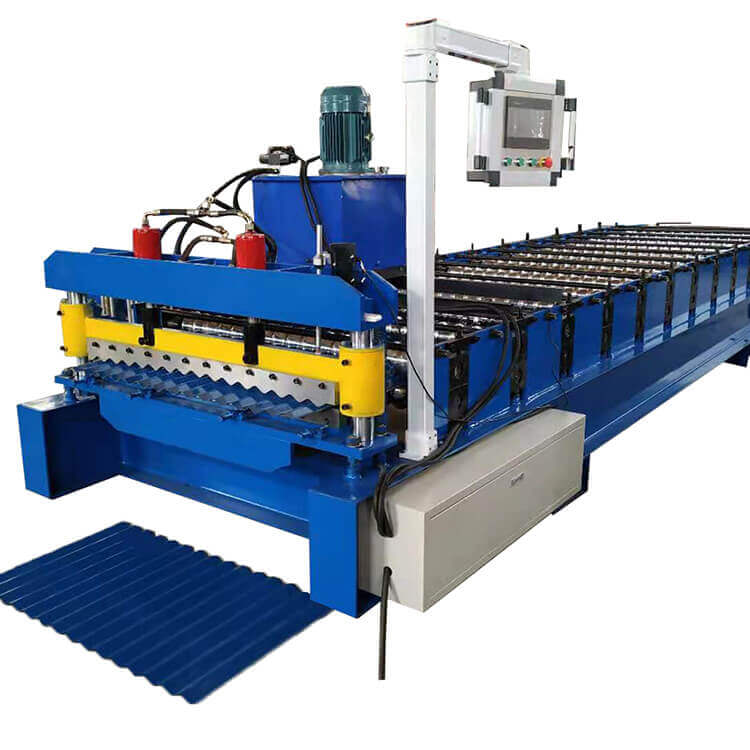

Metal Roof Sheet Corrugated Rolling Making Machine’s technical parameters

| Length of the main part | About10500*1650*1500mm |

| Weight of main part | About 9.5 tons |

| Voltage | 380V/50HZ/3Phase (as customer’s request) |

| Roller fixer | Middle plate welded |

| Frame | 350H steel welded |

| Middle plate thickness | 18mm |

| Drive mode | Chain Drice |

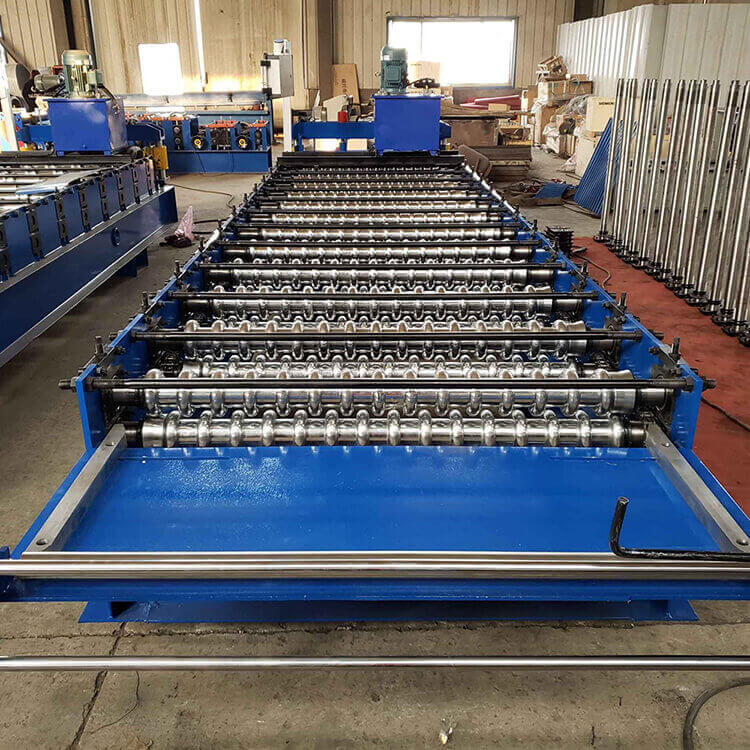

| Material of rollers | 45# steel, surface hard chromium plating. |

| Material of shafts | 45# steel |

| Diameter of shafts | Φ80mm(depend on different design) |

| Number of rollers: | 29 rollers |

| Main power | 5.5kw |

| Cutting&Hydraulic | Double guide pillar |

| Hydraulic motor power | 3kw,4kw |

| Hydraulic Pressure | 10-12MPa |

| Cutting drive | Decelerating motor + Chain drive gear all by high-frequency |

| Control System | PLC system: Mitsubishi, Panasonic,Dental,Siemens,Schneider |

| Feeding Material width | Better as your drawing or from our designer |

| Feeding Thickness | 0.8~1.5mm |

| Effective width | Better as your drawing or from our designer |

| Productivity | 8-12/min |

| Package of machine | Waterproofing membrane, standard export packing |

Metal Roof Sheet Corrugated Rolling Making Machine’s introduction and feature

1. The main parts: roll forming machine; molding press; cutting machine; PLC computer control; hydraulic system.

2. The machine is stable, with no noise, no shake.

3. Controlling by computer, PLC display, the operation is easy, running is steady and reliable, endurable.

4. Cutting machine is characterized by stable driving, easy operation.

5. The hydraulic system uses the CDF-10 hydraulic pump, long operating life, no noise.

6. Material: galvanized, colored steel or aluminum coil.

7. We can make and design the kinds of roll forming machines according to customer’s requests.

Equipment placement:

The base surface of all equipment should be horizontal and hardened. The decoiler, roll forming machine ,center line of the discharge rack, molding machine and discharge table should be on the same straight line, and the left and right sides should not be inclined. The distance between the discharge rack and the forming host should be ≥3m. After the equipment is placed in a stable position, it should be fixed with anchor bolts.