Brief Introduction Of Steel Roof Tiles R Panel Cold Roll Forming Machine

The Roof Panels made by our Steel Roof Tiles R Panel Cold Roll Forming Machine have beautiful appearance and bright color.

They are widely used in gardens, factories, resorts, hotels, exhibition halls, vacationlands, ancient architectures and modern villas.

| Length of the main part | About10500*1650*1500mm |

| Weight of main part | About 9.5 tons |

| Voltage | 380V/50HZ/3Phase (as customer’s request) |

| Roller fixer | Middle plate welded |

| Frame | 350H steel welded |

| Middle plate thickness | 18mm |

| Drive mode | Chain Drice |

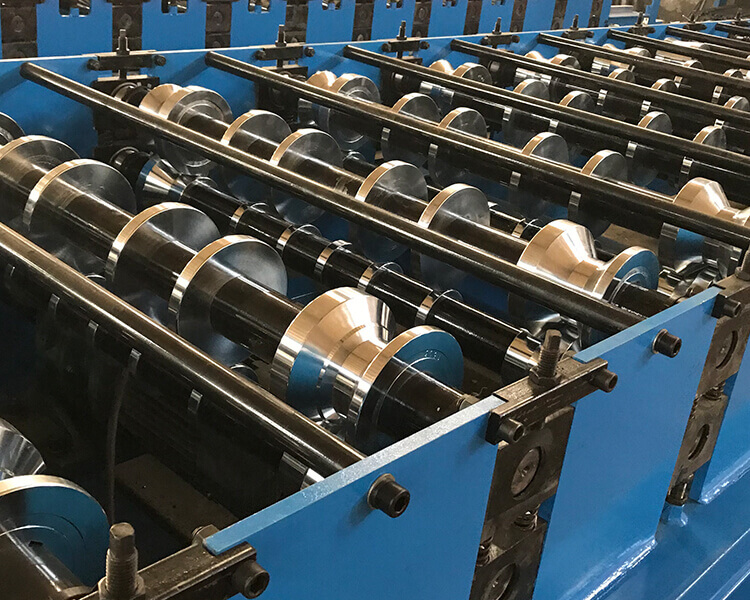

| Material of rollers | 45# steel, surface hard chromium plating. |

| Material of shafts | 45# steel |

| Diameter of shafts | Φ80mm(depend on different design) |

| Number of rollers: | 29 rollers |

| Main power | 5.5kw |

| Cutting&Hydraulic | Double guide pillar |

| Hydraulic motor power | 3kw,4kw |

| Hydraulic Pressure | 10-12MPa |

| Cutting drive | Decelerating motor + Chain drive gear all by high-frequency |

| Control System | PLC system: Mitsubishi, Panasonic,Dental,Siemens,Schneider |

| Feeding Material width | Better as your drawing or from our designer |

| Feeding Thickness | 0.8~1.5mm |

| Effective width | Better as your drawing or from our designer |

| Productivity | 8-12/min |

| Package of machine | Waterproofing membrane, standard export packing |

Steel Roof Tiles R Panel Cold Roll Forming Machine’s introduction and feature

1. The main parts: roll forming machine; molding press; cutting machine; PLC computer control; hydraulic system.

2. The machine is stable, with no noise, no shake.

3. Controlling by computer, PLC display, the operation is easy, running is steady and reliable, endurable.

4. Cutting machine is characterized by stable driving, easy operation.

5. The hydraulic system uses the CDF-10 hydraulic pump, long operating life, no noise.

6. Material: galvanized, colored steel or aluminum coil.

7. We can make and design the kinds of roll forming machines according to customer’s requests.

Equipment placement:

The base surface of all equipment should be horizontal and hardened. The decoiler, roll forming machine ,center line of the discharge rack, molding machine and discharge table should be on the same straight line, and the left and right sides should not be inclined. The distance between the discharge rack and the forming host should be ≥3m. After the equipment is placed in a stable position, it should be fixed with anchor bolts.

About us:

We, Tianjin Haixing is a professional cold roll forming machine manufacturer, We have been focusing on this field for 22 years. Our equipment includes roof roll forming machine, floor deck roll forming machine, automatic decoler, shutter door roll forming machine, light keel roll forming machine, purlin machine, leveling and slitting machine, and other related construction equipment.